Product of ALTRAD plettac-assco GmbH Germany

READ MORE for Plettac Contour Modular Scaffoldingr

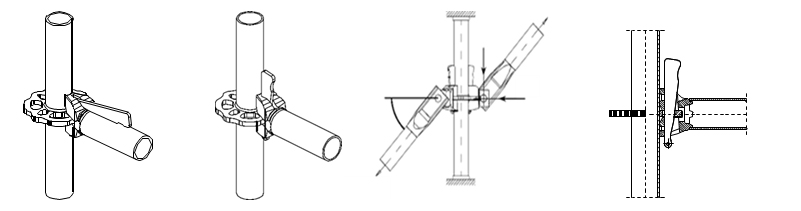

In modular scaffolding, the cross-horizontal bars and the uprights are separate components. At predetermined (modular) distances, disks (rings) with holes are fixed on the supports, which provide the possibility of connecting other elements of the scaffolding, which end at their ends with a connecting head and a fixing wedge.

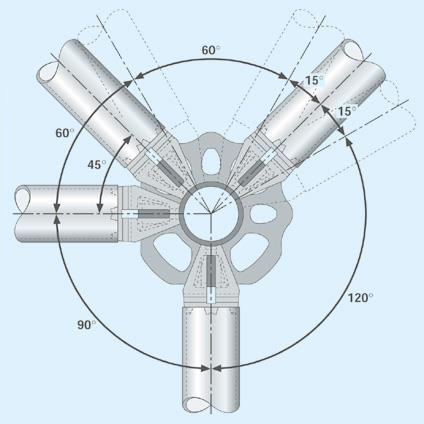

The connection of horizontal and vertical components supporting and strengthening the structure is carried out with a wedge connection. The connection discs have four small holes located at 90°. In this place, the crossbars are connected if it is required to achieve a right angle, which is obtained automatically when wedging. Between the small holes there are four elongated holes that allow the crossbars to be connected at an angle of ±15°. In this way, connections that do not fall into the 90° grid are executed. Joining disks provide the ability to connect up to eight separate components into a single node.

Characteristic of the plettac system are the indentations in the outer edge of the disc, which form not only a specific "contour", but also save its weight, as well as contribute to better arrangement and storage on pallets. Also, due to their non-circular shape, they cannot roll on an inclined surface. Another characteristic feature of the "plettac contour" system is the correct circular shape of all horizontal components. Their shape makes them comfortable and light to use, while at the same time protecting them from collecting and depositing construction waste, chemicals, snow, ice, etc. , which occurs with the systems using a U - beam support system, and which can lead to a shortening of their suitability and a reduction of their operational period. All crossbars are from φ48.3mm diameter scaffold tube. and can be used both for safety railings forming side protection, and for support bars on which the paths lie and form the work site. All system floors, walkways, stairwells and stairs are designed for a tubular support system, which makes it possible to use them also on a simple scaffolding tube with a diameter of φ48.3 mm.. They are equipped with their own locking mechanism against accidental displacement, overturning or lifting due to upward wind load. This avoids the need to purchase and install an additional locking element to secure the floor coverings of the work areas and access stairs.

Another characteristic feature of the system “plettac contur” is the exact metric size of horizontal components with length dimensions of: 15, 25, 41, 50, 74, 75, 100, 110, 125, 139, 150, 175, 200, 250, 300 and 400 cm.. This from its side is an indispensable quality, which in practice makes it possible to symmetrically or asymmetrically divide the work site into 2, 3 or more working fields, as well as to insert into them an additional vertical component, which is necessary at the construction site when overcoming an obstacle, or from which to branch the structure. Makes it easier to calculate, report and/or update!

Made in Germany with approval for use No. Z-8.22-843 issued by the German Institute for Construction Technology. Hot-dip galvanized or aluminum, in accordance with the technical requirements defined by BDS EN 12811.

Price negotiable after formal inquiry!

Installation of modular scaffolding Plettac Contur: